A metal detector is a device that can identify the presence of metallic objects. It works by emitting an electromagnetic field and detecting changes in the field when metal objects are nearby. Metal detectors are commonly used for security purposes, like at airports and in archaeological explorations to find buried artifacts.

Curious if your lost item contains lead? Wondering, ‘Does lead show up on a metal detector?’ You’re not alone. Discover the answer and learn how to find out with a quick and easy call to action in just a few simple steps.

Lead typically does not show up on a standard metal detector because it is a non-ferrous metal. Most metal detectors are designed to detect ferrous metals like iron and steel. However, specialized detectors with lower frequencies may be able to detect lead, but it’s not guaranteed. If you suspect the presence of lead, it’s best to use other testing methods such as X-ray fluorescence (XRF) or chemical tests.

Characteristics of Lead

Lead is a chemical element known for its unique characteristics. One notable trait is its non-ferrous nature, meaning it doesn’t contain iron, which is a common feature in metals detected by standard metal detectors. Another important characteristic is its relatively low electrical conductivity. This property makes lead less responsive to the electromagnetic fields emitted by metal detectors, further reducing its detectability.

In addition to its low conductivity, the density and size of lead can affect its detectability. Smaller lead objects may be less likely to trigger a metal detector because they have less metal content and may not disrupt the electromagnetic field as significantly. Understanding these characteristics is crucial when assessing whether lead can be detected by a metal detector or if alternative methods need to be employed for accurate detection.

Non-Ferrous Nature

Non-ferrous metals are those that do not contain iron and are known for their resistance to corrosion and rust. Unlike ferrous metals, such as iron and steel, non-ferrous metals like lead, aluminum, copper, and brass do not exhibit magnetic properties. This means that they do not interact with a standard metal detector’s electromagnetic field in the same way as ferrous materials do, making them less likely to be detected. The non-ferrous nature of certain metals, like lead, presents a challenge for conventional metal detectors because they rely on changes in the magnetic field caused by the presence of metal objects.

In applications where it’s essential to detect non-ferrous metals like lead, specialized metal detectors with lower frequencies or alternative methods, such as X-ray fluorescence (XRF) and chemical tests, become necessary. These techniques can help identify non-ferrous metals accurately, ensuring the safety and integrity of various processes, from industrial quality control to environmental testing.

Low Conductivity

Low conductivity refers to the property of certain materials that resist the flow of electric current. In the context of metal detectors, it is essential to understand that lead, being a non-ferrous metal, has low conductivity. This property poses a challenge when it comes to detecting lead with a standard metal detector. Low-conductivity metals do not disrupt the electromagnetic field generated by the detector as significantly as highly conductive metals like copper or aluminum.

As a result, the signal produced by lead is often too weak to trigger the detector’s alert mechanism, making it difficult to identify lead objects using conventional metal detection methods. In practice, the low conductivity of lead means that specialized metal detectors or alternative testing methods, like X-ray fluorescence or chemical analysis, are necessary to effectively detect the presence of lead in various applications, from safety assessments to historical artifact identification.

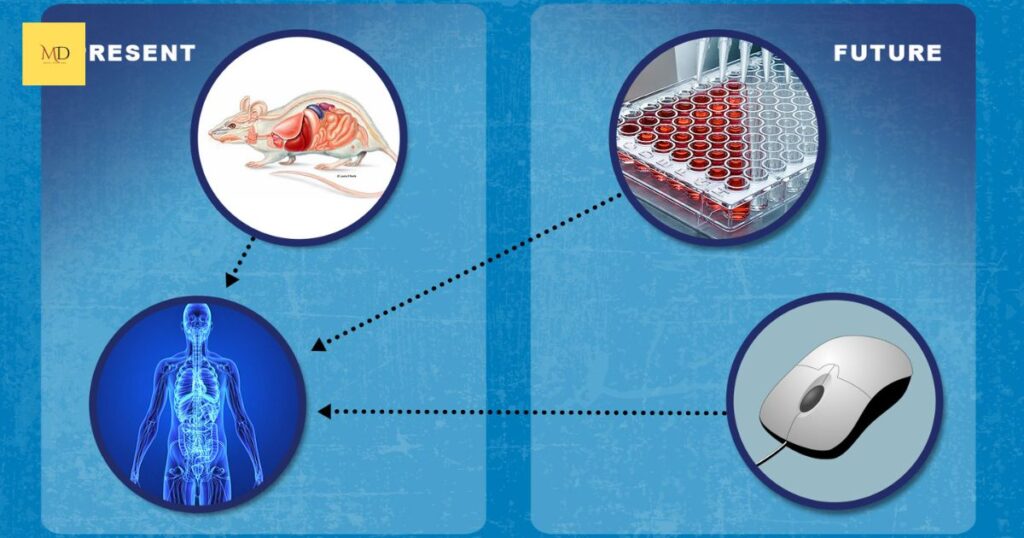

Alternative Methods for Lead Detection

Alternative methods for lead detection are crucial when traditional metal detectors fall short. One widely-used technique is X-ray Fluorescence (XRF), which involves using X-ray technology to excite the atoms in a material. When lead is present, it emits characteristic X-ray fluorescence, which can be detected and analyzed. This method is highly effective in identifying lead content in a variety of materials, making it a valuable tool for industries, environmental assessments, and even in identifying potential lead hazards.

Chemical testing is another alternative approach to lead detection. It involves using specific chemical solutions that react with lead to produce visible color changes. These color changes can indicate the presence of lead in a sample, making it a cost-effective and accessible method for testing lead in various materials. While not as fast or precise as XRF, chemical testing can still provide valuable insights into lead content and is often used for quick on-site assessments.

Chemical Testing

Chemical testing is a method used to analyze the composition of materials by performing chemical reactions on a sample. In this process, specific reagents or chemicals are applied to a sample, and the reactions that occur can reveal the presence of certain substances. It is a valuable technique for identifying and confirming the composition of various materials, including metals, minerals, and compounds. Chemical testing is commonly used in industries such as metallurgy, pharmaceuticals, and environmental science, where precise knowledge of a material’s composition is essential for quality control, safety, and research purposes.

Chemical testing can be a highly accurate and reliable means of identifying the presence of substances like lead, which may not be detectable by other methods such as metal detectors. By carefully selecting the appropriate reagents and conducting controlled tests, analysts can determine the chemical composition of a sample and, in the case of lead, provide a definitive answer regarding its presence. This method is indispensable in various fields, ensuring that products are safe and materials meet specific quality standards.

Visual Inspection

Visual inspection is a simple yet crucial method for detecting various characteristics and issues in a wide range of applications. It involves a thorough examination of an object, material, or area using the naked eye or with the help of basic tools like magnifying glasses or microscopes. This method is commonly used in quality control processes, safety checks, and even archaeological investigations. By relying on keen observation and attention to detail, visual inspection can identify visible defects, irregularities, or anomalies, ensuring the quality and integrity of the subject under examination.

In manufacturing and construction, visual inspection is an essential part of the quality assurance process. Workers and inspectors visually examine products, components, and structures to check for any surface imperfections, structural issues, or compliance with established standards. Visual inspection can also be a valuable tool in fields like healthcare, where medical professionals use it to assess the physical condition of patients or the quality of medical equipment.

FAQ’s

What metals Cannot be detected by a metal detector?

Non-ferrous metals like aluminum, brass, copper, and lead are typically more challenging to detect with a standard metal detector because they lack magnetic properties.

Can a magnet detect lead?

No, a magnet cannot detect lead. Lead is not attracted to magnets because it is a non-ferrous metal and lacks magnetic properties.

What metals set off metal detectors?

Metals that set off metal detectors are typically those with good electrical conductivity, such as ferrous metals like iron and steel, non-ferrous metals like copper, aluminum, and gold, and other alloys that contain these metals.

Conclusion

Metal detectors are valuable tools in various industries, from security and construction to treasure hunting and archaeological research. These devices work by detecting the presence of metals with good electrical conductivity, and they play a crucial role in enhancing safety, ensuring product quality, and uncovering hidden treasures. Whether it’s at an airport security checkpoint or on a beach in search of buried artifacts, metal detectors serve their purpose effectively.

They can identify a wide range of metals, from common ferrous and non-ferrous metals to precious metals like gold and silver. However, it’s important to recognize that not all metals are easily detected, as those with low conductivity may not trigger a response from standard metal detectors. Understanding how metal detectors function and the types of metals they can detect is essential for their successful application in various fields.