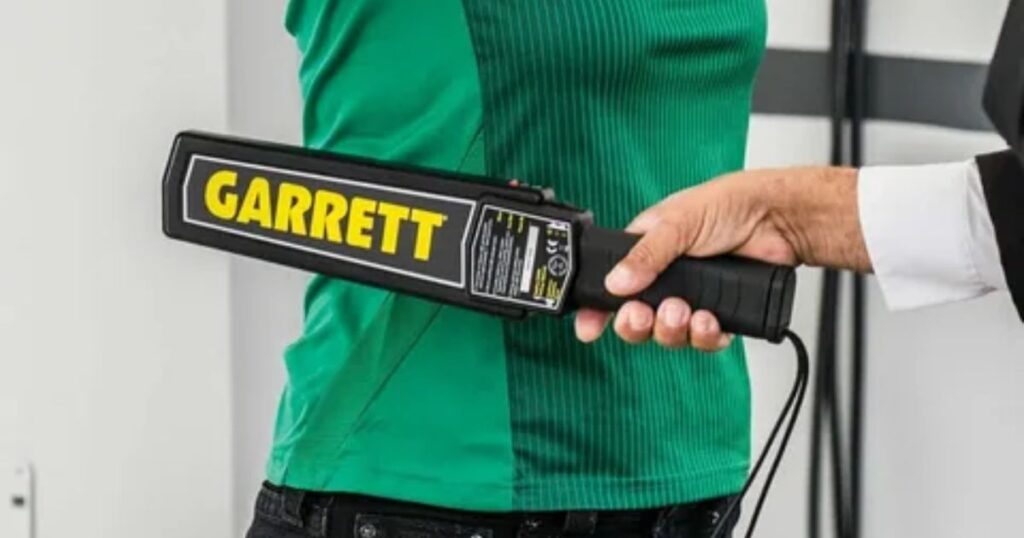

Curiosity and anticipation fill the air as we delve into the intriguing question: Does aluminum set off metal detectors? In this article, we explore the mysterious relationship between aluminum and metal detectors. By unraveling the inner workings of these detection devices, we aim to provide a comprehensive understanding of how they perceive and interact with aluminum. Join us on this captivating journey, as we uncover the secrets behind the detection capabilities of metal detectors when it comes to this versatile metal.

Key Takeaways

- Aluminum is detectable by metal detectors due to its conductive properties, even though it is a non-ferrous metal.

- Metal detectors emit an electromagnetic field that is disturbed by aluminum, which is then detected by the receiver coil.

- Sensitivity settings and the size of the aluminum object can affect the detection of aluminum by metal detectors.

- Aluminum foil can create signal interference and trigger false alarms, and it can also be used to shield or reduce the detection of other metals.

How Metal Detectors Detect Aluminum

Metal detectors are able to accurately detect aluminum through their use of electromagnetic fields. Aluminum is a non-ferrous metal, meaning it does not contain iron, which is commonly detected by metal detectors. However, aluminum is still detectable due to its conductive properties. When a metal detector is turned on, it emits an electromagnetic field. As this field encounters any metal object, including aluminum, it causes a disturbance in the field. The disturbance is detected by the metal detector’s receiver coil, which then alerts the user to the presence of metal. Understanding how metal detectors detect aluminum is crucial for those who desire belonging in the metal detecting community. It allows users to effectively differentiate between various types of metals and enhances their overall metal detecting experience.

Understanding Metal Detector Functionality

Continuing from the previous subtopic, it is important to understand the functionality of metal detectors in order to develop a comprehensive understanding of how they detect various types of metals, including aluminum.

- Electromagnetic Fields: Metal detectors work by generating a magnetic field and then measuring the disturbance caused by metallic objects. When a metal object, such as aluminum, comes into contact with the electromagnetic field, it creates an eddy current that alters the magnetic field.

- Detection Coils: Metal detectors consist of one or more coils that transmit and receive the electromagnetic signals. The size and configuration of these coils determine the metal detector’s sensitivity and range.

- Discrimination Modes: Metal detectors can be programmed to discriminate between different types of metals. They use various techniques, such as target identification and conductivity analysis, to distinguish between valuable and unwanted metals.

- Sensitivity Settings: Metal detectors can be adjusted to different sensitivity levels, allowing users to customize their search for specific metal types. By adjusting the sensitivity, users can focus on detecting smaller or larger metal objects.

Understanding the functionality of metal detectors helps users make informed decisions when it comes to metal detection, ensuring efficient and accurate results.

Setting Up a Metal Detector for Aluminum Detection

To optimize the detection of aluminum, proper configuration of the metal detector is essential. When setting up a metal detector for aluminum detection, there are a few important factors to consider. Firstly, the sensitivity of the detector needs to be adjusted to ensure it can detect the presence of aluminum. This can be done by adjusting the sensitivity settings on the metal detector control panel. Additionally, it is important to select the appropriate search coil for aluminum detection. Certain coils are specifically designed to enhance the detection of aluminum, so it is crucial to choose the right one for optimal results. Lastly, it is important to ensure that the metal detector is calibrated properly to minimize false alarms and interference. By following these steps, you can maximize the chances of detecting aluminum accurately and efficiently.

Variations in Metal Detector Capability for Aluminum Detection

The capability of metal detectors to detect aluminum exhibits variations based on their design and specifications. Here are some factors that contribute to these variations:

- Frequency range: Metal detectors operate within specific frequency ranges. Some detectors may have a lower frequency range, making it more difficult to detect aluminum, while others may have a higher frequency range, increasing the chances of detection.

- Sensitivity settings: Metal detectors can be adjusted to different sensitivity levels. Higher sensitivity settings increase the likelihood of detecting smaller aluminum objects, while lower settings may only detect larger pieces.

- Coil shape and size: The shape and size of the metal detector’s coil can affect its ability to detect aluminum. Different coil designs may be more effective at detecting aluminum in certain orientations or depths.

- Signal processing algorithms: Metal detectors use signal processing algorithms to analyze the received signals and distinguish between different types of metals. The efficiency and accuracy of these algorithms can vary, impacting the detector’s ability to detect aluminum.

Understanding these variations can help individuals choose the right metal detector for their specific needs and increase the chances of successfully detecting aluminum objects.

Aluminum’s Interaction With Metal Detectors

Aluminum interacts with metal detectors differently depending on their design and specifications. The table below outlines the general interaction between aluminum and metal detectors:

| Metal Detector Type | Aluminum Interaction |

|---|---|

| Very Low Frequency | Detects aluminum |

| Pulse Induction | Detects aluminum |

| Beat Frequency | Detects aluminum |

As shown in the table, all three types of metal detectors are capable of detecting aluminum. This means that if you were to pass through a metal detector with aluminum on your person, it would likely set off the alarm. However, it is important to note that the sensitivity of the metal detector and the size of the aluminum object can affect the detection. In the next section, we will explore the role of aluminum foil in metal detection and how it can impact the accuracy of the detection process.

The Role of Aluminum Foil in Metal Detection

When considering the detection of metals, it is important to explore the specific impact that aluminum foil has on the metal detection process.

- Signal Interference: Aluminum foil can create a significant signal interference when passing through a metal detector. Its high electrical conductivity and ability to reflect electromagnetic waves make it easily detectable by metal detectors.

- False Alarms: Due to its sensitivity to metal detection, aluminum foil can often trigger false alarms, causing inconvenience and delays for individuals passing through security checkpoints.

- Shielding Effect: Aluminum foil can be used as a shielding material to block or reduce the detection of other metals. This can be useful in certain applications where the presence of specific metals needs to be concealed.

- Detection Limitations: While aluminum foil is easily detectable, it does not pose a threat to security as it is not considered a dangerous material. However, its presence may mask the detection of other potentially harmful metal objects.

Understanding the role of aluminum foil in metal detection is crucial for accurately identifying and assessing potential security risks.

Factors Affecting Aluminum Detection by Metal Detectors

Factors influencing the detection of aluminum by metal detectors include its electrical conductivity and ability to reflect electromagnetic waves. Aluminum is a non-ferrous metal, meaning it does not contain iron, which is commonly detected by metal detectors. However, aluminum has a high electrical conductivity, allowing it to conduct electric current and create a disturbance in the electromagnetic field produced by metal detectors. This disturbance can be detected by metal detectors, leading to the identification of aluminum objects. Additionally, aluminum has a high reflectivity for electromagnetic waves, which can cause it to appear more prominently on metal detector scans. These factors contribute to the detectability of aluminum by metal detectors, making them effective in identifying aluminum objects in various settings.

Exploring the Relationship Between Aluminum and Metal Detectors

One key aspect to consider when exploring the relationship between aluminum and Metal detectors is the interaction between the electrical conductivity of aluminum and the electromagnetic field produced by metal detectors. This interaction plays a crucial role in determining whether aluminum will set off a metal detector or not. Here are four important points to understand this relationship:

- Electrical Conductivity: Aluminum is a highly conductive metal, meaning it allows the flow of electric current easily. This property enables aluminum to interact with the electromagnetic field produced by metal detectors.

- Eddy Currents: When an electromagnetic field encounters aluminum, it induces eddy currents within the metal. These currents generate their own magnetic fields, which subsequently interact with the metal detector’s field.

- Signal Disturbance: The presence of eddy currents and their magnetic fields can disrupt the original electromagnetic field of the metal detector. This disturbance is detected by the metal detector and can trigger an alarm.

- Thickness and Shape: The size, shape, and thickness of the aluminum object also influence the interaction with the metal detector. Thicker and larger aluminum objects are more likely to be detected compared to thin or small pieces.

Understanding the relationship between aluminum and metal detectors helps explain why aluminum objects can set off metal detectors, making it an essential consideration for security screenings and other applications.

Conclusion

In conclusion, the theory that aluminum sets off metal detectors is true. Metal detectors are designed to detect the presence of metal objects, including aluminum. However, the effectiveness of detecting aluminum may vary depending on the specific metal detector and its settings. Factors such as the size and shape of the aluminum object can also affect its detectability. Therefore, it is important to consider these factors when setting up a metal detector for aluminum detection.